____________________ > Ava

> System components

> Old Style

> Tools

> 48†x 168†cincinnati hydrotel horizontal milling

48†x 168†cincinnati hydrotel horizontal milling

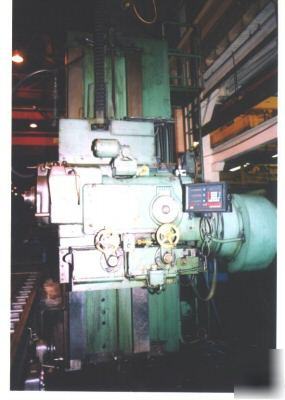

48 x 168 CINCINNATI Horizontal Hy-dro-tel Milling Machine with independent motorized dovetail overarm vertical attachment, S/N 59M-410-R-841-1, new 1959, factory rebuilt

Table working surface: 40 x 191

Table size overall: 52 x 208

Table longitudinal travel: 168

Spindle carrier vertical travel: 72

Maximum height spindle center to

Cross adjustment of spindle carrier: 18

Maximum height center of overarm spindle in

horizontal position to table: 92

Maximum height of face of overarm spindle

Maximum distance horizontal spindle to outer

Taper in horizontal spindle: No. 60 with No. 50 adapter

Taper in vertical overarm spindle: No. 50

Height table top to floor: 33

Maximum swivel of vertical overarm spindle: 360

(16) horizontal spindle speeds: 14-1057 RPM

(8) vertical overarm spindle speeds: 50-750 RPM

Longitudinal and vertical feed range: 0-50 IPM

5 H.P. independently motorized vertical overarm attachment with 360 swivel, No. 50 taper,

Motorized movement to overarm attachment

Power rapid traverse vertical and longitudinal travels

Hand feed controls to table and cross travel of spindle carrier

Newall DP-7 3-axes digital readouts

Built-in auger type automatic chip conveyor

Large quantity of set-up and tie-down tooling with steel storage cabinet

20 H.P. 3/60/220-440 volt Racine hydraulic power unit

50 H.P. 3/60/440 volt main drive motor with controls

Machine wired for 3/60/440 volt operation

Overall dimensions without overarm attachment: 416 L x 158 W x 179 High

Overall dimensions with overarm attachment: 416 L x 173 W x 179 High

Approximate total weight: 111,000 lbs.