____________________ > Ava

> System components

> Old Style

> Hydrolic Components

> JLWT1 cnc milling engrave pcb complete machine sherline

JLWT1 cnc milling engrave pcb complete machine sherline

JLW Model T1 Mini Multi function CNC milling /engraving machine Complete System.

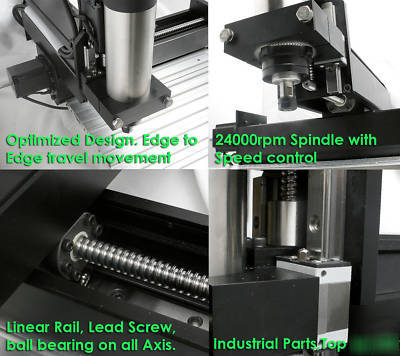

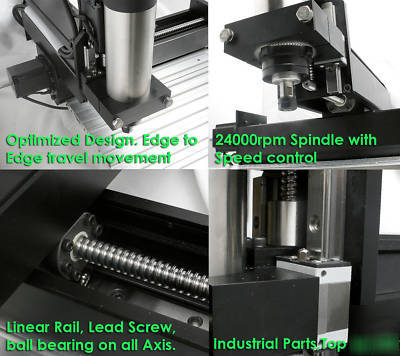

Don t be confuse with the low entry price point of this machine, This is a unique machine that get your investment worth every dollar. The high quality industrial parts such as linear rail and ball bearing lead screw, High speed spindle motor and NEMA23 stepping motor make this package a real workhorse instead of hobby toy. This is ALL metal machine for real application.

Machine also build by high cost custom mold aluminum support parts, light weight yet optimized design allow the travel of all axis as far as possible, Extend the working area up to letter or A4 size.

Table top arrangement also give high level of Flexibility, Various clamping can be apply to different material by total 10 T slot on the table. Very long material such as wood can be engraving section after section with this small machine. For aluminum, dip pan and coolant can be easily install without worry any mechanical precision parts underneath. Since the special design of the machine that all mechanical movement are above the Z level, Machine can even be mount on top of the material and directly engrave on it, if object size is tool large in some case ( engraving on material already fixed on wall).

The controller unit provide a single Emergency stop switch but if your country need 2 stop switch in front of the machine, it can be easily add with our E-stop option.

Compact machine, large working area, edge to edge machine travel limited allow high workability with this light weight, small size machine. ( machine weight 25kg/55lb with spindle motor)

Industrial grade component in all Axis, Z Axis use Dual linear rail, All ball bearing lead screw and double bearing mounting, Our design goal is a small size but real machine, not a toy.

High speed precision spindle motor with modbus speed control, ER16 collet, micro-stepping stepping motor with high current power supply. Simple parallel+ serial input.

Lead screw with Double bearing mount, reliable industrial standard.

Custom mold aluminum parts, design just for best performance of this machine.

Simple yet elegant limited switch location, easy to replace or access.

Tight cutting point to support distance minimized vibration.

Speed controller unit can be install beside the machine for quick access of front panel speed control and display. Can also install away from machine and use the Computer UI control.

Suitable for various material, Plastic, metal, PCB, fiberglass etc.

Complete plug and play system, only required software for PC and PC set up. Machine ready to cut out of the box.

Maximum Travel length : X 300mm/11.8 Y: 200mm/7.87 Z: 60mm/2.35

Table Size: 380mm/14.9 x 240mm/9.44

Table Type: 10 x T Slot, Extruded Aluminum, 10mm Thickness

Total Weight: 25kg/ 55lbs CNC machine

11kg/ 24lbs Controller + spindle speed control

Maximum , Y axis extended to the back, D 521-672mm/20.5 -26.4 x W 543mm/ 21.3 x H 412mm / 16.22

3 x micro stepping controller unit. 40V 3.5A for each motor with force air cooling.

Optical isolated connection to PC.

E-switch, limited switch and aux input to parallel port.

Water splash proof 6 DIN connection cable for all stepping motor.

Spindle and Speed Control Unit:

65MM 1500w high speed double angular contact ball bearing.

4000-24000rpm speed and direction control by modbus command , front panel, or 0-10V speed control voltage. 220V or 110V spindle power input.

Front panel can be select to display RPM, voltage, current, Frequency.

3 x NEMA 23 double shaft stepping motor

1 x Spindle speed control phase converter 1500W

1 x Stepping motor controller unit

1 x L mounting bracket for speed control unit

All purchased are final, will replace defective product and parts only.