____________________ > Aurora

> System components

> New Style

> Motor Parts

> Electric Motor Parts

> Amada 10'-11"X1X4/6 bi-metal svglb cobalt bandsaw blade

Amada 10'-11"X1X4/6 bi-metal svglb cobalt bandsaw blade

2pcs New Amada 10'-11" x 1" x .035 x 4/6 SVGLB M42 Cobalt Bi-Metal Varied Pitch Bandsaw Blade

Amada has been manufacturing bandsaw machines and bandsaw blades for decades. They offer a broad selection of blade types to cover a broad range of cutting materials. Amada has factory weld centers and factory specialist in allmost every state in the USA.

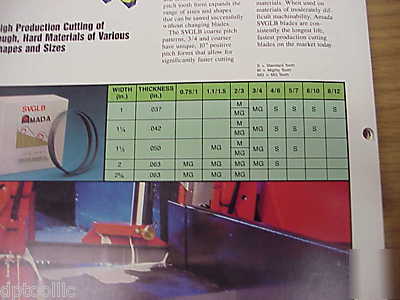

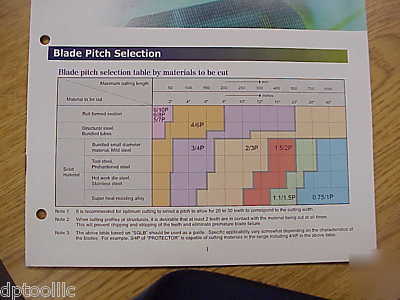

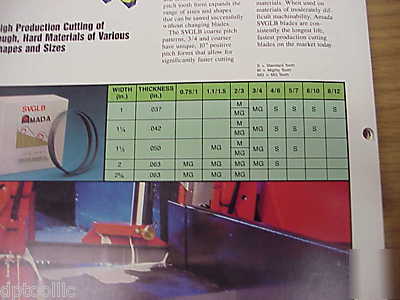

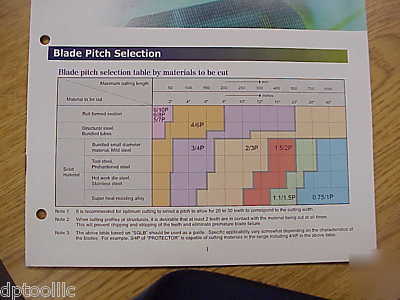

Applications for the SVGLB blades are: P-2, S-2, L-6, D-2 Tool Steels, H-13, 304, 17-4Ph Stainless Steels, 4140, 4320, 4118, 5015 Steels. This blade can also be used to cu high alloy materials such as Titanium, Inconel, and Monel. A band saw specification slide rule chart will be supplied with your order. This chart makes it easy to determine bandsaw cutting feeds and speeds for a variety of metals. See the pictures of this chart below.

The size of material to cut with the 4/6 variable pitch should be a solid material. If you are sawing exotic metals your cutting size range is 1.00" to 2.500" diameter. If you are sawing structual steel, bundled tubes or a roll formed section your cutting size range is 2.00" to 8.00" in solid material. The variable tooth design reduces harmonic vibration resulting in a quieter running blade that cuts smoother and last longer. These bandsaw blades are made from spring tempered, steel backing with an M42 (8% Cobalt) cutting edge.

* Blade Pitch: 4/6 Varied Pitch

* Tooth Geometry: 10 Degree Positive Rake

* Qty. Available: 2 (sold as each)

We have some Suggestions on How to Increase the Tool Life of your bandsaw blades.

Break-In new bandsaw blades when you do your first cut. The break-in process is quick (about 30 seconds) and simple. When you break-in the blade you are honing a very sharp edge and removing any minute burrs left on the blade from milling or grinding the tooth profile. The recommended break-in procedure is to reduce your bandsaw speed 20% below your normal operating speed and reduce your feed rate 50% when you do your first cut. You are finished breaking in the blade when the blade makes 5 complete revolutions while in the cut. The reason for the temporary reduced feeds and speeds is to reduce the amount of vibration to the blade during this time.

Make sure your water soluble coolant is mixed rich enough. The primary functions of a coolant is to prevent chip welding and premature dulling of the blade.The coolant also serves to keep your machine lubricated and to prevent rust on the cut part. The mixture ratio average is to 1 part coolant concentrate added to 5 parts water. Always add your coolant concentrate to your water in a seperate container and then add it to your bandsaw. If you add the coolant to the water you will have trouble with it blending together properly and you will start seing layer of seperation. An Oil based water soluble coolant is best. Synthetic and Semi-synthetic water soluble coolants do not have the lubricity characteristics and rust prevention qualities that an oil based coolant has. If you do not have a refractometer to gauge your coolant mixture you can check it by letting a couple drops of coolant onto two of your fingers from coolant that is coming from the nozzel hitting the bandsaw blade. Rub those fingers together and if it feels like a hand lotion that does not go away your mixture ratio is close enough. If you feel friction your coolant is too weak.

Other causes of premature blade failure are the blade guides are too tight, the blade guides are too far apart, blade tension too low, part not secure or positioned properly in the vise, feed pressure to high or blade speed too slow.

We are a tool grinding and tool supply sales and service company. We have a large inventory of surplus cutting tools and a tool and cutter grinding department that is equipped with 33 machines. 75% of our team has a minimum of 28 years experience each in the metal cutting field. Our best product is our people.