____________________ > Auburn

> System components

> Old Style

> Motor Components

> Diesel Motor Components

> Carpentry + wood as engineering material +: 8 manual cd

Carpentry + wood as engineering material +: 8 manual cd

(TRAINING COURSE AND REFERENCE GUIDE)

(WOOD AS AN ENGINEERING MATERIAL)

consisting of 7 training manuals/subcourses 1607 pages of self-study material with diagrams and illustrations - written by the Army Institute for Professional Development and the United States Department of Agriculture, and 15 Carpentry and Masonry lessons some of which contain step-by-step instructions with illustrations.

This CD is created and produced by planet-e-tech from non-copyrighted, public domain, declassified or

non-classified US Government documents, and is designed to work under Windows operating system

(the .pdf files are also viewable under other platforms, but some automatic features are likely to be disabled).

All the manuals on this CD are in Adobe Acrobat (.pdf) format, and the latest version of Adobe Acrobat

Reader is also included on this CD for your convenience.

Preview 21 pages from CARPENTRY manual: 0.5 Mb

5. CONSTRUCTION PRINT READING (500 pp)

6. FRAME STRUCTURES (135 pp)

7. WOOD HANDBOOK WOOD AS AN ENGINEERING MATERIAL (489 pp)

8. CARPENTRY AND MASONRY LESSONS (15 lessons)

This manual is intended for use as a training guide and reference text for engineer personnel

responsible for planning and executing theater of operations (TO) construction. It provides techniques and

procedures for frame construction, preparation and use of bills of materials (BOMs), building layout,

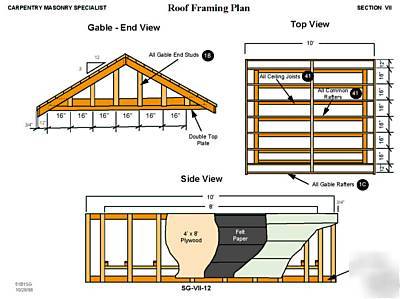

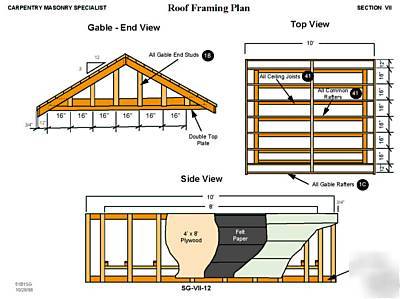

forming for concrete slabs and foundations, framing and finish carpentry, roof framing and coverings,

bridge and wharf construction, and the materials used for these operations.

Chapter 1. - Construction Drawings

q Architectural Symbols, Line Conventions, and Material Conventions

Chapter 2. - Construction Planning and Materials

Chapter 3. - Bills of Materials

Chapter 4. - Building Layout and Foundation

o Laying Out a Rectangular Building Site

o Laying Out an Irregular Building Site

Chapter 5. - Forms for Concrete

o Foundation and Footing Forms

o Floor Joists for Platform Construction

o Plumbed Posts and Straightened Walls

Chapter 7. - Roof Systems and Coverings

o Asphalt and Asbestos-Cement Roofing

o Asphalt-Prepared Roll Roofings

Chapter 8. - Doors and Windows

q Interior Wall and Partition Coverings

Chapter 10. - Nonstandard Fixed Bridge

Chapter 11. - Timber-Pile Wharves

o Pile Clusters and Corner Fenders

o Floating Log Fenders (Camels)

Appendix A. - Conversion Tables

Appendix B. Carpentry Abbreviations and Symbols

Appendix C. - Manpower Estimates

Appendix D. - General Information

o Ceramic and Other Specialty Tiles

This course is designed to give you practical knowledge of basic carpentry.

You will learn to read, understand, and interpret construction prints (also called working drawings);

to identify, use, and requisition building materials; and to care for and use hand tools and power machinery.

Lesson 1: Construction Prints and Building Materials

q Part A: Construction Prints for Buildings

q Part B: Bill of Materials (BOMs)

q Part A: Care and Use of Hand Tools

q Part B: Care and Use of Power Machinery

The Carpentry II subcourse will provide you with enough knowledge to construct floor

systems, stairs, wall systems (including the installation of windows and door), and roof systems of wooden structures.

Lesson 2: Wall-System and Stairway Construction

q Part C: Roof-Covering Material

This subcourse concludes the instruction on carpentry. It discusses the requirements for competent cabinet work, explaining the kinds and selections of woods, the classification and uses of woodworking joints, and the standards for their employment. The selection of materials for constructing wooden articles, the assembling of parts into units, and the steps taken in a final inspection of completed work are presented in sequence.

3. HEAVY TIMBER CONSTRUCTION

The Army's scientific advancement places an ever-increasing demand on the technical capabilities of its personnel. The technical know-how of greater numbers of troops must be improved through training. Each individual is obligated to keep abreast of this progress. Construction print reading is a key skill for technical students. Fortunately, a formal education is not essential for achieving proficiency in this important subject; the study of correspondence courses such as this can provide the essential skills.

The objective of this subcourse is to provide you with the fundamentals of planning and

supervising the construction of frame structures which comprise the basic type of building in a theater of

operations. It will also orient you in the fundamentals of construction print reading. You will learn about

building layout procedures; framing details of substructures, superstructures, and roofs; kinds and

properties of timber; and planning and estimating material and labor requirements for frame construction.

Emphasis is on simplified theater-of-operations construction. However, some details of conventional

construction are also included for use as a general guide and for use in rehabilitation and repair of existing

q Lesson 1. Construction Print Reading - Building Layout and Substructures.

q Lesson 2. Superstructures - Framing.

q Lesson 3. Roofing-Finishing Details.

q Lesson 4. Materials Estimating.

q Lesson 5. Construction Methods and Standards - Planning Estimates.

WOOD HANDBOOK - WOOD AS AN ENGINEERING MATERIAL

Summarizes information on wood as an engineering material. Presents properties of wood

and wood-based products of particular concern to the architect and engineer. Includes discussion of

designing with wood and wood-based products along with some pertinent uses.

q Chapter 1 Characteristics and Availability of Commercially Important Wood

Bark, Wood, Branches, and Cambium

q Chapter 3 Physical Properties and Moisture Relations of Wood

Weight, Density, and Specific Gravity

q Chapter 4 Mechanical Properties of Wood

Mechanical Properties of Clear Straight-Grained Wood

Natural Characteristics Affecting Mechanical Properties

Effects of Manufacturing and Service Environments

Commonly Used Lumber Abbreviations

q Chapter 6 Lumber Stress Grades and Design Properties

Responsibilities and Standards for Stress Grading

Visually Graded Structural Lumber

Machine-Graded Structural Lumber

Adjustment of Properties for Design Use

q Chapter 8 Structural Analysis Equations

q Chapter 9 Adhesive Bonding of Wood Materials

Surface Properties of Wood Adherends

Physical Properties of Wood Adherends

q Chapter 10 Wood-Based Composites and Panel Products

Types of Conventional Composite Materials

General Manufacturing Issues

Standards for Wood-Based Panels

Particle and Fiber Composites

q Chapter 11 Glued Structural Members

Glued Members With Lumber and Panels

Structural Sandwich Construction

q Chapter 12 Drying and Control of Moisture Content and Dimensional Changes

Determination of Moisture Content

Recommended Moisture Content

Moisture Control During Transit and Storage

Design Factors Affecting Dimensional Change

Wood Care and Installation During Construction

q Chapter 13 Biodeterioration of Wood

Marine Borer Damage and Control

q Chapter 14 Wood Preservation

Effect of Species on Penetration

Preparation of Timber for Treatment

Application of Preservatives

Quality Assurance for Treated Wood

q Chapter 15 Finishing of Wood

Factors Affecting Finish Performance

Control of Water or Moisture in Wood

Types of Exterior Wood Finishes

Application of Wood Finishes

Finish Failure or Discoloration

Finishes for Items Used for Food

Wood Cleaners and Brighteners

q Chapter 16 Use of Wood In Building and Bridges

Post-Frame and Pole Buildings

Considerations for Wood Buildings

Fire Safety Design and Evaluation

Fire Performance Characteristics of Wood

q Chapter 18 Round Timbers and Ties

Standards and Specifications

q Chapter 19 Specialty Treatments

Paper-Based Plastic Laminates

Various PowerPoint Lessons (converted to .pdf) from CARPENTRY AND MASONRY

1. Wood Frame Construction 8x8.pdf

2. Prepare a Carpentry Materials Takeoff List.pdf

3. Fabricate Joints and Splices.pdf

4. Install Exterior Finish.pdf

5. Construct a Concrete Wall Form.pdf

6. Construct Column and Overhead Forms.pdf

7. Construct a Concrete Slab Form.pdf

9. Construct a Masonry Wall.pdf

10. Construct a Wall System.pdf

11. Construct a Floor System.pdf

13. Construct a Roof System.pdf

15. Install Doors and Windows.pdf