____________________ > Albion

> System components

> Old Style

> Hydrolic Components

> High pressure Components

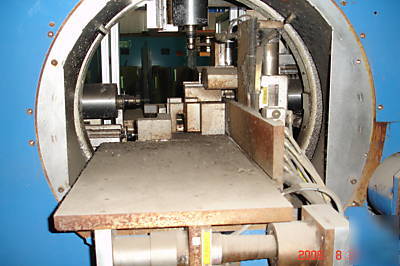

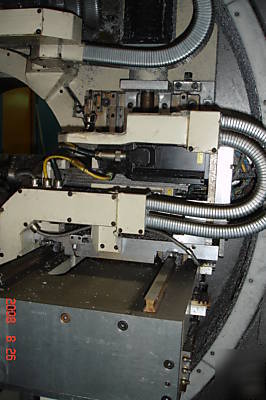

> Extech xt-2000 multi axis mill for machining extrusions

Extech xt-2000 multi axis mill for machining extrusions

EXTECH XT-2000 MULTI AXIS MILL FOR MACHINING EXTRUSIONS

3. Control Allen Bradley 10XX CNC

4. Control uses G and M codes

5. Machine comes with software disks

6. Machine comes with following manuals : operators, control functions, operator maintenance, G and M code tables error codes/messages and table editor manual, Microsoft windows with DOS system, Fisher spindles, application manual for control, language and plus edit, library user, asset language, mini DNC Serial, and DOS real time interface, servo drives with analog interface.

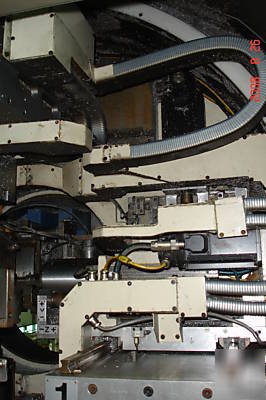

7. Required tool holder HSK-A40

8. Spindle type Fisher MWFS-1230/5218 (4 ea.)

9. Maximum tool diameter 12mm

10. Tool change (cut to cut) 12 seconds

11. Maximum spindle speed 42,000 rpm s

13. Tool changer (maximum number of tools) 20

15. Brake torque 7.96 (ft lbs)

16. With Volkmann 9000 digital adjustable-speed AC drive (with manual).

18. With pre-run off measuring protocol.

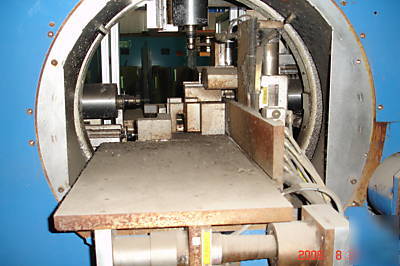

19. With in feed and out feed roller tables. (see pictures)

Pathway run time 2.0 and 4.1.1

Wallongong group pathway access su 3.2 DOS/Windows 3.5

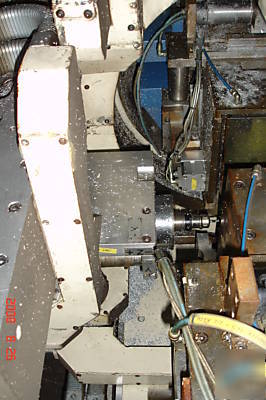

V axis in feeder NC-support +74.0,-13.0mm Max speed - 6 (m/min)

X axis machine centre Spindle +0.3,-288.5mm Max speed 24 (m/min)

Y axis machine centre Spindle +0.3,-284.5mm Max speed 24 (m/min)

Z axis machine centre spindle +0.3<-304.0mm Max speed 24 (m/min)

A axis machine centre Ring +- 180.3 deg Max speed 800 (deg. /min)

P axis machine centre in feed table +50.5-25.1 Max speed 6 (m/min)

Q axis machine centre in feed table +185,-0.3 Max speed 6 (m/min)

D axis machine centre out feed table +54.1,-23.3 Max speed 6 (m/min)

C axis Out feeder Gripper +1,-6236 (mm) max speed 60 (m/min)

W axis Out feeder +56,-27 (mm) Max speed 6 (m/min)

Tool change position X=0 Y=-240.0, Z=0

Electrical requirements 480 Volts 3 Phase

Pneumatic supply Pressure 6 (bar) 87 (psi)

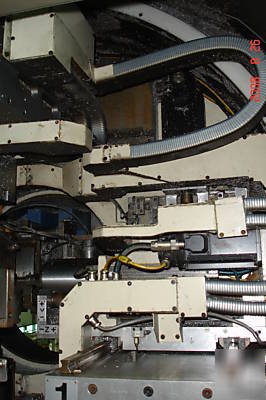

The XT-2000 uses 22 programmable axis, in 4 different processes.

X- Spindle movement in to / out from rotation ring.

Y- Spindle movement up / down (spindle in position kl 3)

V- support-movement in feed side

W- support-movement out feed side

P- Clamp table in jogging direction

Q clam table in parallel to C-axis

D clam table out jogging direction

A,C,V,W,P,Q,D,X,Y,Z and spindle 1

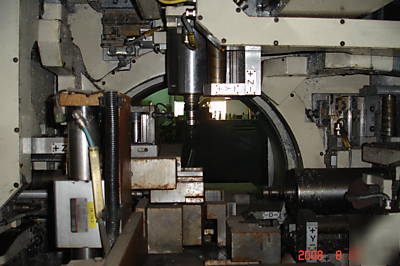

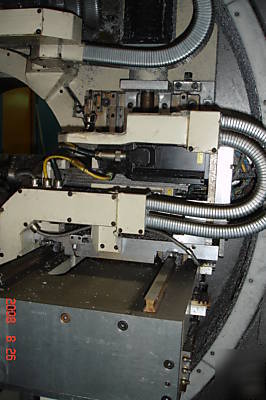

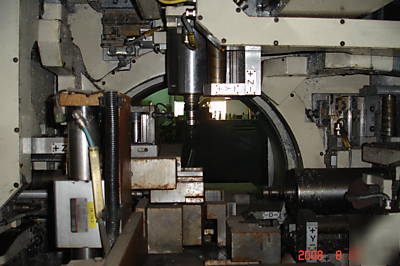

There are four high speed spindle units mounted on a ring. Each spindle can move independently on three axes X, Y and Z using guide rails, ball screws and servomotors.

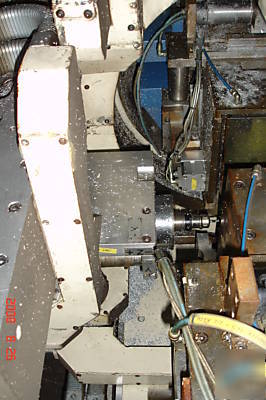

The table holds the profile during machining using two clamps (horizontal/vertical). The vertical clamps can be either fully opened or fully closed. The horizontal clamps can be fully opened, fully closed or opened with a small stroke. When opened with a small stroke the clamp arm will open while the clamp pads still are slightly pressed to the profile (spring pressure). This is to prevent profile from falling off the clamps, during feeding. Clamps are controlled by m-codes.

The table holds the profile during machining using two clamps (horizontal/vertical). The vertical clamps can be either fully opened or fully closed. The horizontal clamps can be full opened or fully closed. Clamps are controlled by M codes.

Purchased from a large aerospace company.

Condition Good, as removed from service.