____________________ > Abingdon

> System components

> Old Style

> Tools

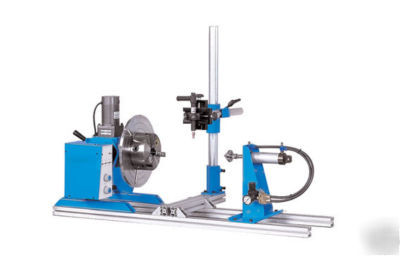

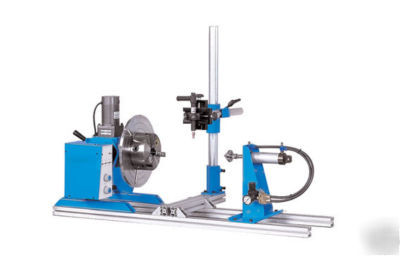

> L-type welding automated system with 60" base rails

L-type welding automated system with 60" base rails

Industrial Welding Automation Equipment

L-Type Automated Systems are a combination of a welding

Positioner and a Kit in bench design. L-Type Kits are designed

with multiple sized rails to cater to different sizes of welding

applications. To order your L-Type Automated system, simply

select a welding positioner, L-Type kit with desired rail length

and any additional accessories. All images are shown with AUT-

PT-100A welding positioner and optional AUT-PG-150 3 Jaw

Automated Systems combine a Welding Positioner and a "Do It

Yourself" Automated Accessory Kit designed for bench top use.

Choose the components you need for your welding application.

Components are easy to change to minimize setup time and

These automated welding systems produce high-quality circumferential

welds, and provide the advantage of fast pay-back, increased safety

To order select the Welding Positioner that best meets your welding application,

then select a "Do It Yourself" Automated Welding Kit and any additional

If you are not sure what you need, or if you have any questions about our

Automated Systems contact our in-house expert.

Do It Yourself Automated Welding Systems Features:

* Standard 1.5" Through Hole

* Remote Foot Switch - ON/OFF Controller

* All Units Are High Frequency Protected

* Weld Timer Control For Precise Adjustment of the Welding Period

* Heat and Spatter Resistant Air Hose

* Optional Flange-Adapting Fixture with Bearing of Any Required Fixture

* Optional CB002 Overweld Control

* Optional CB007 Sequencer Control

* Optional Pneumatic Torch Holders

Available Welding Positioners and Chucks:

* AUT-PT100B - Low Speed - High Torque Positioner

* AUT-PT200B - Low Speed - High Torque Positioner

* AUT-PT100A - High Speed - Low Torque Positioner

* AUT-PT200A - High Speed - Low Torque Positioner

Automated Systems are a combination of a welding Positioner and a

"Do It Yourself" Automated Accessories Kit in bench design. A wide

choice of components creates great flexibility in the automatic welding system.

Components are easy to change to minimize setup time and maximize productivity.

The special capabilities of these automated welding systems produce high

quality circumferential welds, and provides the advantage of fast pay-back,

safety and less worker fatigue. These automated welding systems were designed

for easy ordering capability, just select a welding positioner, then select a "Do It

Yourself" Automated Welding Kit and any additional accessories you may need.