____________________ > Abingdon

> System components

> Old Style

> Hydrolic Components

> High pressure Components

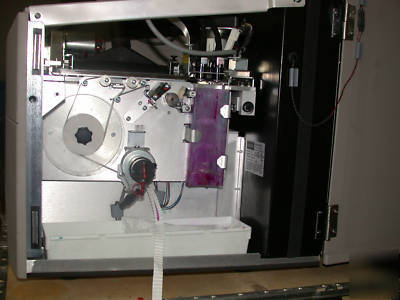

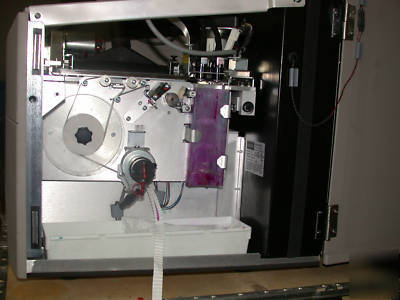

> Solidscape T66BT2- rapid prototype cad/cam

Solidscape T66BT2- rapid prototype cad/cam

The T66 Benchtop reduces your costs and time-to-market by translating CAD designs from most jewelry and engineering design software into 3D casting patterns. Grow models of your most intricate and complex designs with the assurance of results that are geometrically perfect and, in many cases, unable to be produced by hand crafting or by milling systems. Undercuts, overhangs and cavities are no problem because of Solidscape s dissolvable support material structure.

The T66 Benchtop operates on standard current, uses non-toxic build materials and has a small footprint making it truly office friendly. And the consumables? Inexpensive to use when compared to other model building system technologies. All this at a price that won t break the bank.

The High-Precision 3D Modeling System

* Up to 5 times more precise than some other rapid prototyping systems

* Ultra-high resolution: 25M addressable drops per square inch (25.4 mm2)

* Build envelope: 6 x 6 x 6 in. (15.24 x 15.24 x 15.24 cm)

* Build layer: 0.0005 in. (0.013 mm) to 0.0030 in. (0.076 mm)

* Achievable accuracy: +/- 0.001 in. (0.025 mm) per inch in X, Y and Z dimensions

* Surface finish: 32-63 micro-inches (RMS)

* Minimum feature size: 0.010 in. (0.254 mm)

* Automatic generation of model support structure

* Pre-configured build files for "first pass" model success

* "Point and click" access to job status, remaining build time, and other statistics

* Minimal post-processing of model surfaces necessary

* User-adjustable build rate and other parameters

* Built-in, automatic performance monitoring

* Accurate restart of build from point of interruption or power failure

* Direct casting of patterns

* Negligible co-efficient of thermal expansion (prevents casting shell ruptures)

* Fast melt out in autoclave

* No ash or residue contamination

* With build layers as fine as .0005 inches, the T66 Benchtop system delivers higher precision models, prototypes, and patterns than any other pattern making systems.

Compatible with Mold-Making Materials and Process

* Works with silicone, RTV, epoxy, and other elastomeric molds

* Can be used to build injection molding tools

Non-Toxic, Office-Friendly Process

* No facility modifications required

* Uses non-hazardous materials

* Small footprint: 22.0 in. (55.88 cm) wide x 19.5 in. (49.53 cm) deep, 19.5 in. (49.53 cm) high

* Works with standard CAD files: .STL, .SLC

* Operates with standard IBM-compatible PC, running Microsoft Windows 2000 Professional, XP Professional or ME

* Costs less to own and operate than other rapid prototyping systems

* Low system price compared to most rapid prototyping systems

* Meets regulatory compliance: CE; FCC Class A, UL

T66 Benchtop 2 Return on Investment

(Based upon US pricing / 1 year warranty)

Operating Efficiency / Production Planning = 85%

(two models per day, produced by hand)

x $3 Cost of Material For Each Model

$45,650 = Price of T66 Benchtop 2

$45,650 60 Months = $760 per month

$150 Material To Produce 50 Models

$910 Operating Cost for Machine and Material per Month

$200 Typical Cost Each to Purchase Models

$10,000 Estimated Cost to Purchase 50 Models

- $910 Monthly Cost of T66 Benchtop 2 and Materials

$9,185 Monthly Savings using T66 Benchtop 2 to Make Models

$910 Monthly Cost for T66 Benchtop 2 50 Models = $18 per Model

$45,650 Purchase Price of T66 Benchtop 2 $9,090 Monthly Savings = 5 Months

The T66 Benchtop 2 will pay for itself in 5 months producing only 2 models per day