____________________ > Abingdon

> Electronic components

> Aluminium welding, welding rods, stick welding,

Aluminium welding, welding rods, stick welding,

4 Only Aluminium Welding Rods 3.2mm x 350mm long Rods

HARRIS ALUMINIUM DC ARC WELDING ELECTRODES

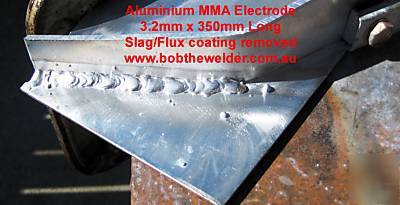

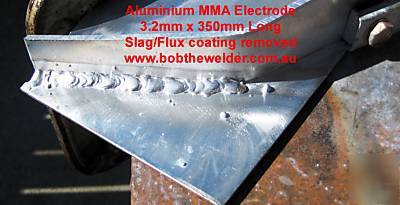

* 4 Only 3.2mm x 350mm Long Flux coated electrodes.

* ALUMINIUM DC MMA WELDING Electrode

*....4 Only 3.2mm x 350mm Long Flux coated electrodes.

*....Universal electrode for welding all cast, wrought and extruded aluminium and aluminium alloys in all positions. *....AWS A5 E 4043

*....Flux Coated electrode providing high speed deposition of dense, machinable welds.

*....Use for fabrication and repair of cast & wrought aluminium, foundry defects, machining errors and salvage work.

*....Ideal for repairs and maintenance.

*....(DC reverse current only).

*....Suggested Amperages 83-135 Amps

*....(They can also be used with a conventional oxy-acetylene torch for gas welding aluminium!)

INSTRUCTIONS as per J.W.HARRIS Co Inc.

3.2mm x 350mm Long Aluminium Electrode (83-135 amps)

* Use Dc reverse polarity only.

* Weld area must be clean and heavier sections should be Vee d or bevelled.

* Preheat heavier (over 6.0mm) sections to 500 F.

* Hold electrode at right angle to work and tilt electrode slightly in direction of travel.

* Slag is easily removable and should be chipped or brushed between passes.

* Tensile strength up to 34,000 Psi

* Extruded Thermo Coating Aluminium alloy for low temperature Arc Welding of all weldable Aluminium s.

*....My own observations are the Electrode are hard to start, and extremely current / amperage sensitive. (Getting the right setting may take time?)

*....Once the arc is started maintain a short arc keeping the electrode within the slag cover, travel is similar to welding with mild steel.

*....Weld appearance will improve with operator experience.